FINITE ELEMENT NUMERICAL ANALYSIS FOR FATIGUE STRENGTH IN FSW WELDING OF ALUMINUM-5052 ALLOY

DOI:

https://doi.org/10.51630/ijes.v6i2.177Keywords:

fatigue analysis, finite element method, friction stir welding, Aluminum 5052Abstract

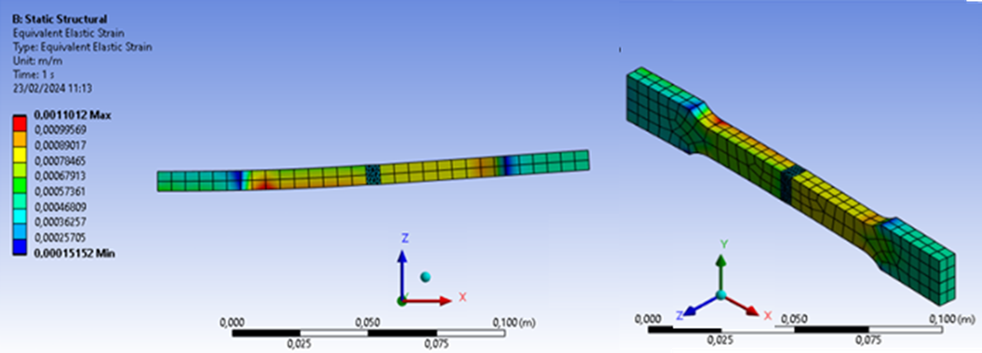

This study applied observations on the fatigue loads of friction stir welding joints of 5052 Aluminum alloy using the finite element method approach. The 3-dimensional model of the test specimen for fatigue loading was designed using CAD software following the ASTM E466 standard. Fatigue loads were simulated numerically using Ansys Workbench software with loading sequences of 5000 N, 10,000 N, 15,000 N, and 20,000 N. The simulation showed a significant increase in equivalent stress from about 9.44e7 Pa to 3.82e8 Pa.. Deformation increased from 0.32 mm to 1.26 mm, while equivalent static strain rose from 0.001 m/m to 0.004 m/m. The S/N curve analysis showed that fatigue life was under 500,000 cycles at loads between 10,000 and 20,000 N, and between 500,000 and 6,000,000 cycles at 5000 to 10,000 N.

Downloads

References

X. Ge, D. Jiang, W. Song, and H. Wang, “Effects of Tool Plunging Path on the Welded Joint Properties of Pinless Friction Stir Spot Welding,” Lubricants, vol. 11, no. 3, p. 150, Mar. 2023, doi: 10.3390/lubricants11030150.

Z. Wang, R. Ye, and J. Xiang, “The performance of textured surface in friction reducing: A review,” Tribol Int, vol. 177, p. 108010, Jan. 2023, doi: 10.1016/j.triboint.2022.108010.

Armansyah, H. H. Chie, J. Saedon, and S. Adenan, “Temperature distribution in friction stir spot welding of aluminium alloy based on finite element analysis,” IOP Conf Ser Earth Environ Sci, vol. 426, no. 1, p. 012127, Feb. 2020, doi: 10.1088/1755-1315/426/1/012127.

Mohd Saiful Bahari, M. Shamil Jaffarullah, Zulkifli Mohamed, and Armansyah, “Heat analysis in friction stir welding using finite element method,” Journal of Mechanical Engineering, vol. SI 5, no. 4, pp. 174–188, Mar. 2018.

B. H. Abed, O. S. Salih, and K. M. Sowoud, “Pinless friction stir spot welding of aluminium alloy with copper interlayer,” Open Engineering, vol. 10, no. 1, pp. 804–813, Sep. 2020, doi: 10.1515/eng-2020-0090.

R. Z. Xu, D. R. Ni, Q. Yang, C. Z. Liu, and Z. Y. Ma, “Pinless Friction Stir Spot Welding of Mg‒3Al‒1Zn Alloy with Zn Interlayer,” J Mater Sci Technol, vol. 32, no. 1, pp. 76–88, Jan. 2016, doi: 10.1016/j.jmst.2015.08.012.

Q. Chu, X. W. Yang, W. Y. Li, and Y. B. Li, “Microstructure and mechanical behaviour of pinless friction stir spot welded AA2198 joints,” Science and Technology of Welding and Joining, vol. 21, no. 3, pp. 164–170, Apr. 2016, doi: 10.1179/1362171815Y.0000000078.

S. S. Parkhe and R. J. Patil, “A Review of Friction Stir Welding and Processing on Aluminium Alloys,” Journal of Mines, Metals and Fuels, pp. 2473–2492, Dec. 2023, doi: 10.18311/jmmf/2023/34919.

Jeroen De Backer, Sam Wei, and Jonathan Martin, “Robotic FSW for three-dimensional components,” in SEEIIW2015 Romania, 2015.

C. Niu, S. Xie, and T. Zhang, “Research on anti-fatigue design method of welded structure oriented to stiffness coordination strategy,” International Journal of Structural Integrity, vol. 13, no. 2, pp. 196–211, Mar. 2022, doi: 10.1108/IJSI-10-2021-0115.

C. Niu, S. Xie, and T. Zhang, “A New Anti-fatigue Design Method for Welded Structures Based on Stiffness Coordination Strategy and Its Application,” 2022, pp. 93–100. doi: 10.1007/978-3-030-97822-8_10.

Peng, Chen, and Dong, “Experimental Data Assessment and Fatigue Design Recommendation for Stainless-Steel Welded Joints,” Metals (Basel), vol. 9, no. 7, p. 723, Jun. 2019, doi: 10.3390/met9070723.

L. Long, X. Zhang, S. Gu, X. Li, X. Cheng, and G. Chen, “Experimental and Simulation Investigation on Fatigue Performance of H13 Steel Tools in Friction Stir Welding of Aluminum Alloys,” Materials, vol. 17, no. 7, p. 1535, Mar. 2024, doi: 10.3390/ma17071535.

V. P. Pervadchuk and A. R. Davydov, “Fatigue tests simulation of materials with a random endurance limit,” J Phys Conf Ser, vol. 1730, no. 1, p. 012006, Jan. 2021, doi: 10.1088/1742-6596/1730/1/012006.

G. Li, H. Zhang, and W. Zang, “Fatigue Crack Growth Performance in Refilled Friction Stir Spot Welding and Friction Stir Welding of Aluminum Alloy Joints,” 2024, pp. 511–524. doi: 10.1007/978-981-99-8861-7_51.

E. M. M. Mubarak, “Experimental and Numerical Study of 6061-T6 AL- Alloy Fatigue Life using Friction Stir Welding,” The Iraqi Journal for Mechanical and Materials Engineering, vol. 18, no. 2, pp. 277–295, Aug. 2018, doi: 10.32852/iqjfmme.Vol18.Iss2.93.

J. Langari, K. Aliakbari, and F. Kolahan, “Fatigue life simulation of AA7075-T651 FSW joints using experimental data,” Eng Fail Anal, vol. 154, p. 107690, Dec. 2023, doi: 10.1016/j.engfailanal.2023.107690.

N. J. Aghdam, S. Hassanifard, M. M. Ettefagh, and A. Nanvayesavojblaghi, “Investigating Fatigue Life Effects on the Vibration Properties in Friction Stir Spot Welding Using Experimental and Finite Element Modal Analysis,” Strojniški vestnik – Journal of Mechanical Engineering, vol. 60, no. 11, pp. 735–741, Nov. 2014, doi: 10.5545/sv-jme.2013.1324.

Y. Jin, Y. Ma, Y. Chen, X. Wang, and T. Guo, “Residual stress effects on fatigue crack growth in different regions of aluminum alloy 7050 friction stir weld,” Fatigue Fract Eng Mater Struct, vol. 46, no. 3, pp. 1093–1106, Mar. 2023, doi: 10.1111/ffe.13923.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Indonesian Journal of Engineering and Science

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.